Having spent half my life handloading ammo I’ve managed to learn some things. Some lessons came easy, and some I learned the hard way. The first case I ever tried to resize became permanently stuck in the die; that’s how I learned the importance of case lube. I write about the actual process of handloading from time to time, but not regularly. Generally, my articles reflect the lessons I’ve learned and my purpose for sharing is to hopefully save someone else the headaches I’ve had to treat with across-the-counter medication or whiskey.

The following four topics have been pulled from my handloading notebook, and they represent some of my hard-earned education. They deal with common issues most reloaders struggle with, and maybe they will help you make more reliable, safe, and accurate ammunition. They might also prevent some of the four-letter words often uttered from behind a press from disturbing your wife’s evening Tupperware party.

Problems With Primers

Some things have been repeated enough they’re now considered fact. This is particularly true when it comes to internal ballistics. To some extent this is because the average guy has no way to definitively measure internal pressures. For most of my handloading life I’ve heard that a pierced primer or a primer that pops out of a fired case is a sure sign of excessive pressure. Truth is, neither are proof positive.

Most commercially manufactured cartridges have a maximum average pressure (MAP) established by Sporting Arms and Ammunition Manufacturer’s Institute (SAAMI). These limits are determined by a number of things, but do not necessarily mean that pressures above MAP will blow guns up or cause high pressure signs. Reliable reloading data is held to these same limits.

A number of rifle cartridges are restricted to pressures of less than 50,000 psi. SAAMI felt this necessary because of the older firearms chambered for these cartridges. There are also high-pressure cartridges that operate near 70,000 psi. Regardless of the round, 70,000 psi is approaching the limit of cartridge brass.

It’s long been an accepted fact that primers popping out of the case when the round is fired are an absolute indication of high pressure. These are usually referred to as blown primers. However, it can also occur because a gas-operated semi-automatic rifle is not properly timed. In other words, the bolt unlocks before the case releases its hold on the chamber and the primer pops out. Jeff Hoffman with Black Hills Ammunition calls these dropped primers.

How do you tell the difference between a dropped and blown primer? Hoffman explained that generally, with a blown primer you’ll see a lot of soot/powder residue around the primer pocket. A more definitive determination is to see if the primer will fit back into the pocket. In the case of a dropped primer it won’t, a blown primer will.

When primers are truly blown this is usually a sign of high pressure, but it does not necessarily mean the ammo is to blame. Dave Emery with Hornady says excessive headspace can cause primers to back, or even pop completely, out. There can be other culprits, like a rifle chamber cut very tightly, a throat that is cut too short, or a barrel with a tight bore. On rare occasions, the cartridge brass might not have been properly annealed. Temperature can also raise pressures.

Pierced primers are often considered a sign of high pressure, too. A primer is pierced where the firing pin punches through the wall of the primer cup. It’s unmistakable when you see it; what’s not is why it happened. For example, I was testing a new rifle a few months back and was seeing pierced primers with a particular ammunition. The designer of the rifle blamed the ammo saying it was “hot,” meaning it was loaded to pressures beyond SAAMI MAP. I doubted this; I’d been using the same ammo, from the same lot, in other rifles without issue. I suggested a problem with the firing pin, but this was met with skepticism. Out in the field that afternoon, I stripped the bolt and worked the firing pin over with a file on a Leatherman tool. The problem vanished.

According to Hoffman, firing pins can be too sharp or too long, and sometimes the aperture—the hole in the bolt the firing pin passes through—can be too large. It’s easy to see how a sharp or lengthy firing pin might pierce a primer, but not as easy to see a cause and effect with a firing pin hole that’s too large. The primer cup is allowed to flow around the firing pin, which allows the cup to thin and lets the firing pin or the hot gas on the other side of the primer punch through.

Bottom line: no matter the cause, blown, dropped, or pierced primers are not normal. They’re an indication something is wrong. Remember, it’s not always high pressure or the fault of the ammunition. Unbelievably, sometimes rifles, just like gun writers, are not perfect.

Powdered Fuel

There are two basic types of smokeless powder; single- and double-based. Single-based powder is made from nitrocellulose. Double-based powder is a combination of nitrocellulose and nitroglycerin. The performance difference between single and double-based powders is not set in stone and it’s hard to quantify. In general, double-based powders burn hotter and dirtier. Sometimes, they are the best choice if maximum velocity is desired, though some believe they cause minutely faster throat erosion in the barrel.

Most all smokeless powders are coated with graphite to keep them from caking, so they will flow through powder measures and funnels with ease. Many are also coated with various chemicals to make them water resistant, control burning, and to reduce muzzle flash. Manufacturers add stabilizers to reduce the risk of deterioration over time.

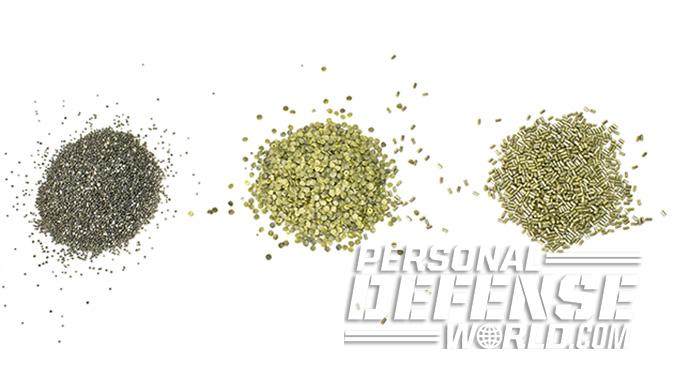

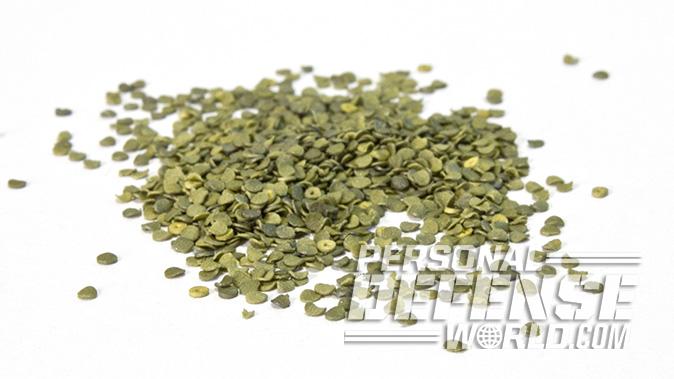

By changing the size and shape of the granules in smokeless powders, the burning characteristics can be controlled. These variations range from flakes as small as ground pepper to cylindrical grains almost as big as a pencil lead. The three most common forms of smokeless powder are flake, ball, and extruded.

Pistol powders are generally fast-burning, double-based powders, just like shotgun powders. Rifle powders are slower burning, but there is some overlap. For example, Hodgdon‘s Lil’ Gun powder was specifically designed for the .410 bore shotgun. But it also performs well in many magnum pistol cartridges and in smallish rifle cartridges like the .22 Hornet and .218 Bee.

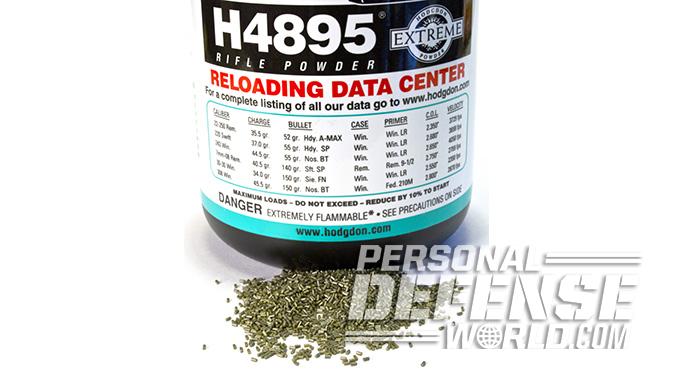

There are a number of things to consider when choosing a power. Foremost is burn rate. Large case capacities generally call for powders with slower burn rates. A slower burning powder will often give better results as bullet weight increases. Burn rate is not all that matters, however. Hodgdon’s H322 and H335 powders have similar burn rates, and both work very well in the .223 Remington. Maximum loads for a 69-grain bullet vary by only one grain and muzzle velocities are almost identical. However, H335 is a double-based ball powder and H332 is one of Hodgdon’s Extreme powders, formulated to show very little velocity deviation over wide temperature variations.

Which is best? It depends. If you expect to be shooting when it’s cold enough for thermal underwear or when it’s warm enough for a Speedo, H322 is probably the best choice. But, rifles are as individual as humans and unpredictable as politicians. Your rifle, or your powder measure, might not like the extruded granules of H322, either.

To load consistent ammunition, you need to fill each case with the same amount of fuel. Extruded powders can bind powder dispensing mechanisms, causing slight variations in charge weight. If you weigh each charge by hand or use an electronic powder dispenser this a non-issue.

One of the best sources for data is the Hodgdon web site. There you can view and compare handload data for just about any cartridge. And, never forget that ballistic technicians from Hodgdon and all the other powder manufacturers, are only a phone call away. You’ll be hard pressed to find better consumer support for any other product, anywhere.

Case Head Swipe

Case head swipe (CHS) with AR-type rifles appears when the ejector and/or extractor cuts in the bolt face mar the case head. It can be an indication of high pressure, that your rifle is not timed for the load you’re shooting, or both. When a cartridge is fired in an AR, the case expands and fuses itself to the chamber until pressure drops and it springs back to near unfired size. As the bullet passes down the barrel it is followed by gas, which creates pressure. When the bullet passes the gas port, gas leaks into it and is diverted to the gas key on the bolt carrier.

Pressure remains until the bullet exits the barrel. The time it takes the bullet to travel from gas port to muzzle exit is called dwell time. Carbine and rifle length barrels have different length gas tubes to optimize dwell time. If too much pressure passes through the gas tube, or if the dwell time is too long, the bolt carrier starts its rearward travel before the case lets go of the chamber. As gas forces the carrier back, the bolt begins to rotate and move backward through the chamber lugs while the cartridge case is still under pressure. This premature rotation causes CHS, where the edges of the ejector and extractor cut-outs in the bolt face scrape the hot and malleable brass of the case head and create bright marks or even burrs.

Minimal CHS can be a sign of high pressure, but more than likely it indicates a timing issue. Certain loads can cause the action to begin working too soon. Because of their different pressure curves, different powders can cause this, too. For example, I loaded the .30 Remington AR with Ramshot Xterminator powder and 110-grain bullets. When I reached a muzzle velocity of 2,860 fps CHS appeared. I switched to Alliant Reloader 10X and achieved the same velocity with no CHS. I then tried Hodgdon’s H322 and pushed the 110-grain bullet to just over 3,000 fps with no CHS. All these powders have similar burn rates.

If you’re seeing moderate to excessive CHS there’s a problem. Barring another sign of high pressure, CHS is probably not dangerous. Keep in mind that brass from some manufacturers may be softer and this can exaggerate these marks. It’s common for many AR-15s and AR-10s show minimal head swipe with some factory pressure-safe loads.

The ominous blown primer is generally considered a true sign of high pressure, but I suggest you refer back to the first section of this handbook on problems with primers. Case head swipe can even appear on just some of the ejected cases out of the same lot of factory or handloaded ammunition because peak pressure can vary a great deal between rounds out of the same lot; as much as 4,000 psi.

Excessive CHS can mar case heads so badly they’ll not fit into the shell holder when reloading. You can easily fix this with a flat file, but the real solution is to cure the problem. You can back the powder charge down or switch powders and maybe even primers. Another way to correct for case head swipe is to alter the timing of the AR. You can do this by switching to a heavier recoil spring, weighting the buffer, installing an adjustable gas block, or any combination of these. But when I see anything beyond minimal case head swipe on any of my AR handloads, I fix the problem by fixing the load.

Sizing Cases

Accurate ammunition is usually very straight or concentric, meaning that when loaded, the neck and the bullet are parallel with the centerline of the case. Start a bullet down a barrel straight and it will generally come out that way. To make bullet and neck run-out measurements you’ll need a gauge like the Case Master from RCBS. Checking bullet and case neck run-out is not the only thing you can do with this tool, however. It will also let you measure neck thickness, check to see if cases need to be trimmed, and check for case head separation.

Several times I’ve sorted factory ammunition to separate rounds with more than.003-inch of bullet run-out from those with less. In almost every instance, the cartridges with less than .003-inch run-out shot smaller groups.

To check the concentricity of a loaded cartridge, place it on the Case Master so the ball tip rests against the bullet about .1 of an inch ahead of the case mouth. Holding the case firmly down, rotate it down and back against the V-block and stop pin of the Case Master. While you do this, watch the dial indicator. It will wobble slightly and may move as little as .001 of an inch. If you’re looking for precision accuracy you want bullet run-out of less than .003-inch. Most factory ammunition will average about .005. This is acceptable for most big game hunting but less run-out is desirable if you’re varmint hunting or plan on shooting at long range.

You can check the bullet run-out of all your handloads if you can afford to devote the time. I generally only check every cartridge when I am working up a load because it eliminates an unknown from the equation during development. Because I try to build concentric ammunition right from the get go, I’ll only check the run-out of the first few loaded rounds once I’ve settled on a particular load, and then maybe every 10th round or so.

Checking the concentricity of your brass is the smart thing to do. You can do this with the RCBS Case Master, too. Just position the case so the ball tip rests on the case neck near the case mouth. First, check the concentricity of fired brass. This will tell you if the chamber in your rifle is cut straight. If you are seeing a neck run-out of more than .001-inch in fired brass, you have a rifle problem.

If fired brass shows little or no run-out, size five cases and check the run-out of each. If it’s over, or varies more than .001-inch, you have a problem with your sizing die and it’s likely the expander ball that’s causing it. Remove the expander rod and ball and run those same five cases back through the sizing die. Odds are case neck run-out will

drop below .003-inch for every case.

I rarely use the expander ball when sizing cases. Most often I’ll replace it with the die with one from the next smallest caliber so I can continue to de-prime while sizing. Otherwise I’ll use a universal de-capping die to de-prime first. Yes, it adds an extra step but ensures cases are concentric. It also leaves the case mouth about .003- to .005-inch smaller than what it would be if the expander ball were used. I’ve yet to see this cause a problem when seating bullets, especially if the inside of the case mouth has been chamfered.

For More Information

Rimshot

ramshot.com

Alliant

alliantpowder.com

Hodgdon

hodgdonreloading.com